Making a ballet tutu can be a very rewarding experience. To see your costumes on stage after a long process of creating them creates feelings of pride and accomplishment, following carefully sewing on hooks and eyes, and creating layers and layers for the finished product.

Making a ballet tutu can be a very rewarding experience. To see your costumes on stage after a long process of creating them creates feelings of pride and accomplishment, following carefully sewing on hooks and eyes, and creating layers and layers for the finished product.

For large scale companies and individual commissions the process is the same. For individual commissions, with perhaps one seamstress, it is a lot of hard work and long hours so they may only take on a few each season. For larger companies the work load is much heavier because of the all the programme demands and the dancers’ needs. The techniques to create tutus have mostly been in use since the 1800s; for many companies the bodices are made of cotton coutil, the same fabric used for corsets. This is extremely strong, but it is comfortable too and absorbs sweat.

A tutu is a pancake style skirt that sticks out from the dancer’s body, originally designed to show off the dancer’s legs and intricate footwork. Generally there are ten rows of ruffles forming a tutu, some of which use multiple layers of net and tulle, and often the cost of individual commissions can rise to hundreds or thousands of pounds. These one-of-a-kind costumes are completely special to the customer but part of everyday life for designers and creators.

Each tutu begins by making the knicker part, and from there the tutu itself is built and the bodice is constructed. For both aspiring and company dancers, the costume must be a perfect fit: the dancers often want them as tight as possible in order for them to feel more secure when performing. The tutus are designed to last a long time, enduring many performances, possibly many dancers and other wear and tear factors too. Performing on different stages also takes its toll however the costumes prevail.

Whilst the stereotypical uniform for dance is much the same, different uniform is required for different dance schools, different exam boards and even different dance grades. For a non-dancer, the assumption of pink ballet tights and a leotard for ballet is not so far from the truth, the stereotypes also formed for tap and modern jazz. Contemporary and lyrical classes tend to be a little more free and liberal in terms of what the dancer dons, and can range from anything to short shorts and tights tops to tracksuit bottoms and baggy pyjama-style tops, known on the whole as ‘baggies’, often used in any dance class for warming up.

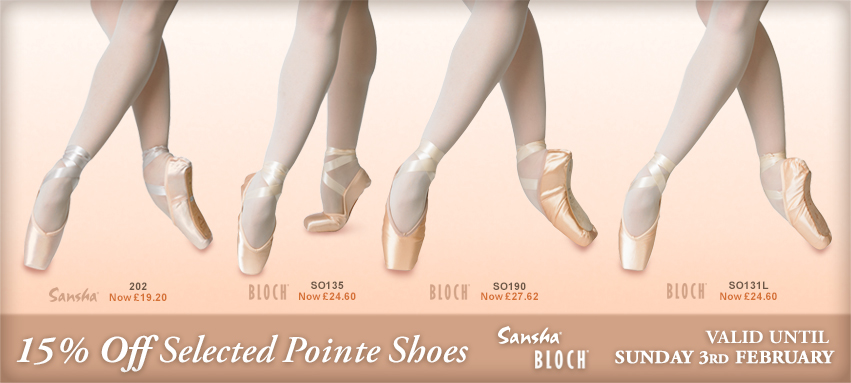

Whilst the stereotypical uniform for dance is much the same, different uniform is required for different dance schools, different exam boards and even different dance grades. For a non-dancer, the assumption of pink ballet tights and a leotard for ballet is not so far from the truth, the stereotypes also formed for tap and modern jazz. Contemporary and lyrical classes tend to be a little more free and liberal in terms of what the dancer dons, and can range from anything to short shorts and tights tops to tracksuit bottoms and baggy pyjama-style tops, known on the whole as ‘baggies’, often used in any dance class for warming up. It is that time of year again, when summer school places are booked up and participants are eagerly waving their practice shoes and leg warmers, impatient for the summer holidays when they can either continue or intensify their training over the sunny weeks ahead. Whilst there are a great many summer courses, school workshops, classes and more on offer to the dedicated dance student, all require one thing: a checklist of dance shoes and practice clothes.

It is that time of year again, when summer school places are booked up and participants are eagerly waving their practice shoes and leg warmers, impatient for the summer holidays when they can either continue or intensify their training over the sunny weeks ahead. Whilst there are a great many summer courses, school workshops, classes and more on offer to the dedicated dance student, all require one thing: a checklist of dance shoes and practice clothes.